How Freeze-Drying Technology Is Transforming Institutional Food Systems

Food waste in institutional kitchens is becoming a priority sustainability issue. Large institutions are starting to treat surplus vegetables as an asset rather than waste, and freeze-drying is emerging as one of the most promising ways to turn leftover produce into shelf-stable ‘stealth-health’ ingredients for the next day’s menu. While pilots are still early and often bundled under broader ‘food tech’ or dehydration programs, the economics and nutrition science behind freeze-drying and vegetable powders already point toward a viable, scalable tool for school districts, hospitals, and corporate cafeterias.

The Hidden Problem: Institutional Food Waste

Hospitals, schools, and corporate canteens throw away vast amounts of edible food because of forecasting errors, strict nutrition standards, and safety rules around holding times. School and institutional catering systems face similar patterns: central kitchens must over-produce to guarantee every child or staff member can be fed, yet plate waste, serving waste, and unserved surplus are all common. International guidance for food-service institutions now explicitly urges operators to measure and manage food loss and waste as a climate and cost issue, not just a hygiene concern.

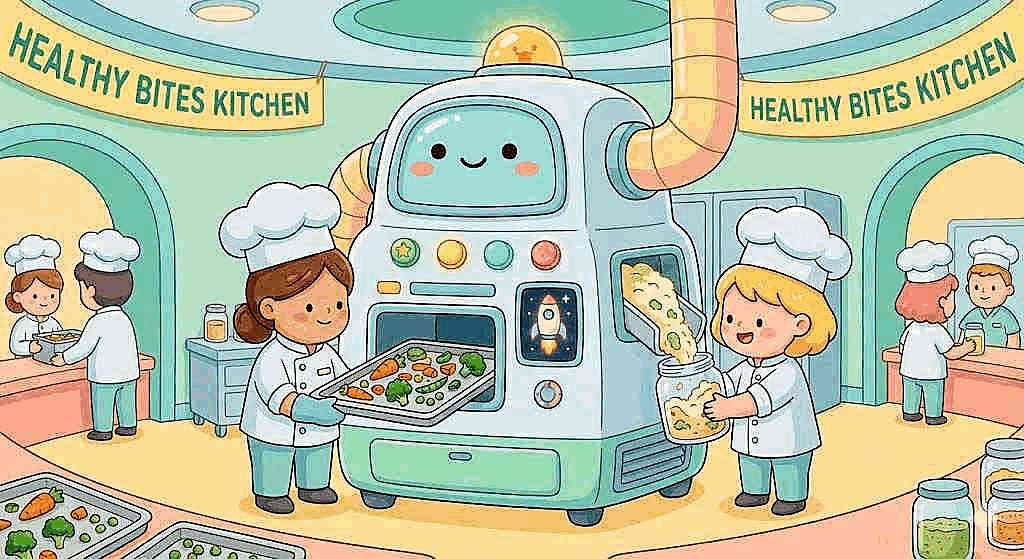

Why Freeze-Drying Is Attractive For Institutional Kitchens

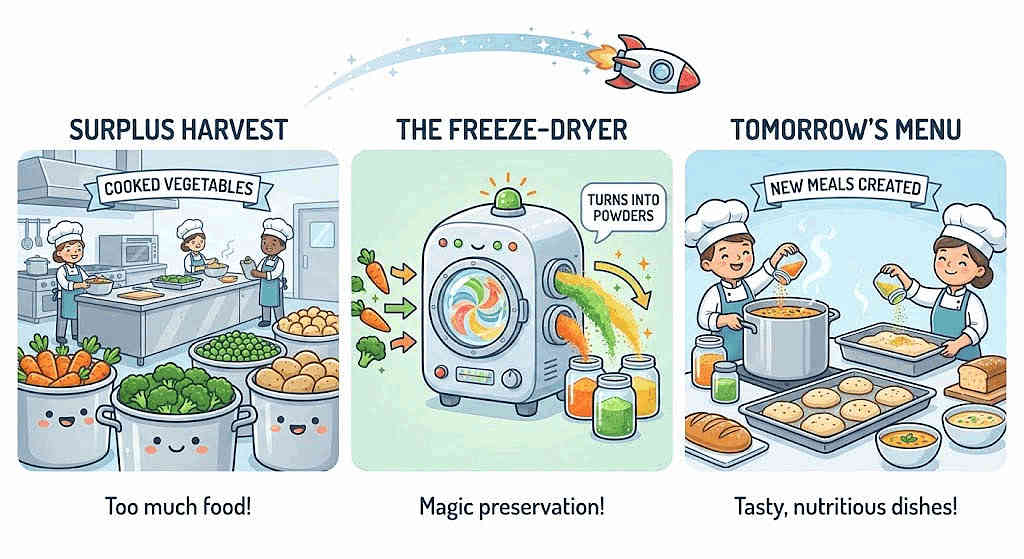

Freeze-drying (originally refined for space missions) removes water at low temperature so that fruits and vegetables retain most of their colour, flavor, and micronutrients while becoming extremely light and shelf-stable. For institutional kitchens, this means yesterday’s steamed broccoli or roasted squash does not have to be binned or composted. Instead, it can be blended, frozen, and freeze-dried into concentrated vegetable powders that can later be whisked into pasta sauces, soups, or smoothies with minimal impact on taste and texture.

Economics and Scalability in Big Kitchens

The economics hinge on a trade-off: freeze-dryers are relatively capital-intensive and energy-demanding, but institutional kitchens generate predictable, high volumes of similar ingredients and have strong incentives to cut waste-related costs. When those wasted vegetables are transformed into shelf-stable powders, they can displace purchased ingredients (for example, part of the tomato paste in a sauce or the fruit puree in a smoothie base), effectively turning a cost center into a source of internal value.

Stealth-Health and Nutrition Benefits

“Stealth nutrition” strategies that sneak vegetables into familiar foods have been evaluated in both clinical and practical contexts, with several studies concluding that covertly boosting vegetable content can increase overall vegetable intake and reduce energy density without harming acceptance. For school meal programs and hospital cafeterias, adding freeze-dried broccoli, carrot, or pumpkin powder into pasta sauces, baked goods, or smoothies is a way to raise the vegetable “baseline” in menus, especially for groups who often fall short of recommended intakes.

Where THOSE USAGE Today

Documented examples of surplus-to-powder initiatives tend to appear under broader food-rescue or food-tech projects rather than institution-specific pilots, but they still point to the same underlying model. Some companies now partner with growers, processors, and community kitchens to freeze-dry surplus fruits and vegetables into instant soups and smoothie mixes, explicitly framing this as a way to capture nutrition that would otherwise be lost. As technology costs fall and policy instruments begin to reward measurable reductions in food waste, it is plausible that central school kitchens, hospital systems, and large corporate caterers will pilot shared freeze-drying units, acting as “mini space-tech hubs” in the middle of public food systems.

Sources

- NHS Hospital Food Waste Cost – WRAP & Sustainable Healthcare Coalition. https://www.bergmanndirect.co.uk/articles/how-can-nhs-hospitals-handle-food-waste-compliantly

- Hospital Foodservice Waste Audit – Collins, J., et al. (2023). https://pubmed.ncbi.nlm.nih.gov/36690908/

- School Food Waste Statistics – BioteCH4 & Food Waste Education Sector Analysis. https://biotech4.co.uk/food-waste-in-the-education-sector/

- Freeze-Drying Nutrient Retention https://ifanca.org/resources/from-freeze-to-feast-the-art-and-science-of-freeze-drying/

- NASA and Freeze-Drying Technology – NASA Spinoff Historical Records. https://spinoff.nasa.gov/Spinoff2020/cg_2.html

- Stealth Nutrition Strategy Effectiveness – Spill, M. K., et al. (2011). https://pmc.ncbi.nlm.nih.gov/articles/PMC3155937/

- Hidden Costs of Food Waste in Institutions – University of Portsmouth & ECR Retail Loss (2025). https://www.port.ac.uk/news-events-and-blogs/news/new-research-reveals-the-ps78-billion-hidden-cost-of-managing-unsold-and-surplus-food

- Plate Waste Forecasting in Schools – Plate Waste Forecasting Using Monte Carlo Method (2022). https://pmc.ncbi.nlm.nih.gov/articles/PMC8840275/

- UK School Food Waste Reduction – Testing interventions to reduce food waste in school catering. https://www.sciencedirect.com/science/article/pii/S0921344921006066

- Institutional Food Waste Management Guidance – Scoping review on reducing food waste in healthcare (2025). https://www.sciencedirect.com/science/article/pii/S0213911125000160

- Tastybubu News and Learning Articles